The economic loss caused by liquid metal corrosion to China's metallurgical industry is very serious, and there is also a potential threat to the normal operation of nuclear power stations. Thermal spraying technology has more than 80 years of development history, its application fields are very wide. The technology has been successfully applied in anti-corrosion, which has extended the service life of the workpiece, reduced the generation cost of the enterprise and the maintenance cost of the equipment, and played an indispensable role in the development of national economy.

In the field of liquid metal corrosion resistance, China has done a lot of long-term and research work, especially in the metallurgical industry components (including large cold and hot rollers), from equipment materials and processes, have entered the engineering application stage, and achieved significant technical and economic benefits.

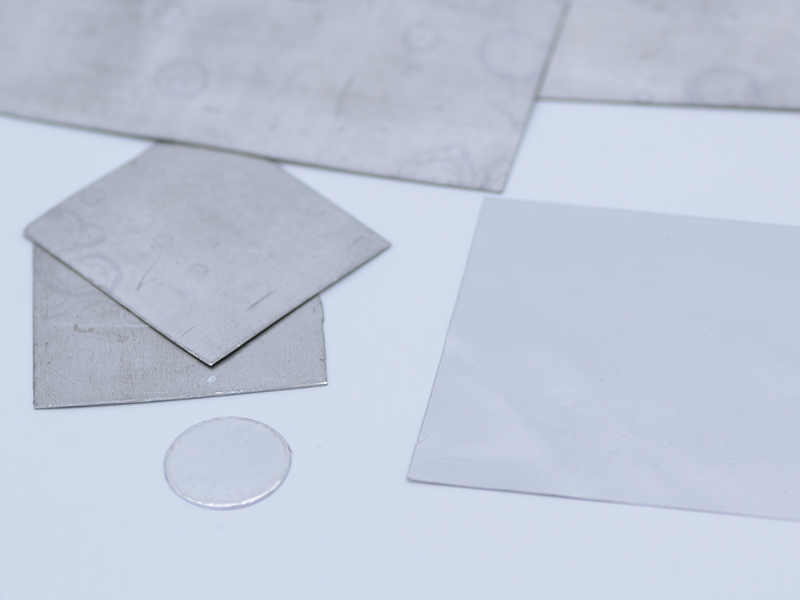

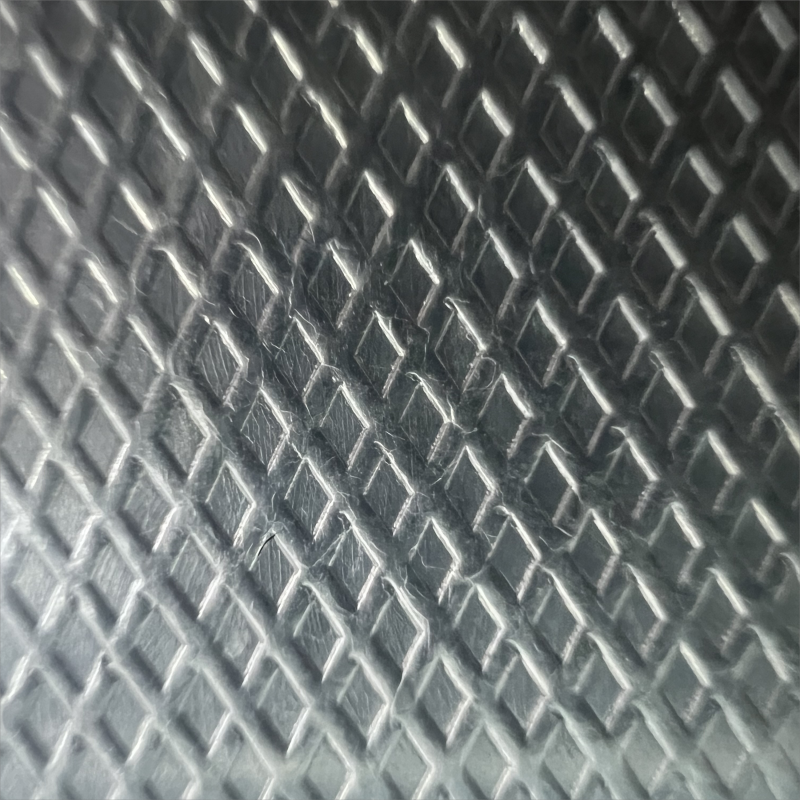

In recent years with the development of thermal spraying technology and related materials, process and improve, this technology is also referenced to corrosion resistance to molten metal engineering, domestic related units and some colleges also did a lot of work, such as in material aspect, has successfully developed the can be used in corrosion resistance to molten metal to 3 oxidation 2 aluminium (Al2O3) as the main products of oxidation ceramic series thermal spraying powder materials, some units also have copied out of the plasma, supersonic thermal spray equipment and plasma equipment, the supersonic electric arc, basic comparable to similar foreign products in performance.

Want to know more about liquid metal corrosion?