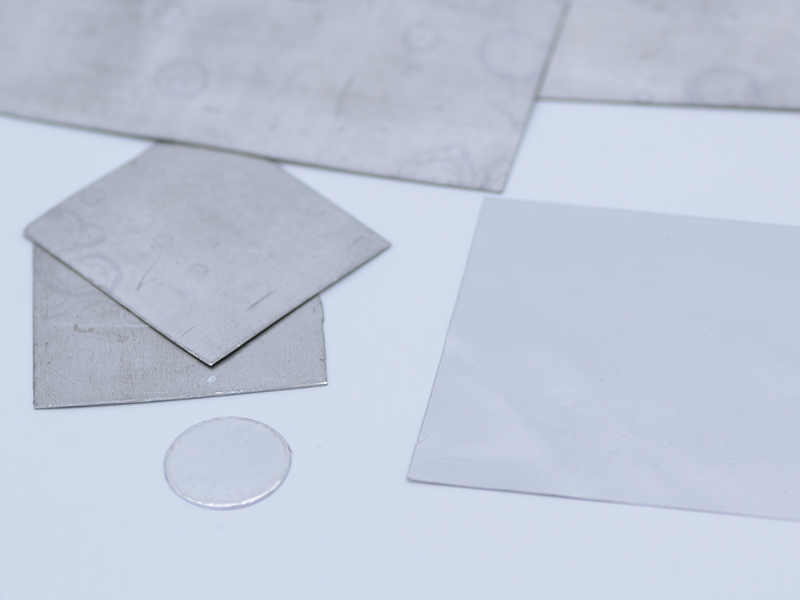

The low melting point alloy and polymer

composite can be used not only for the preparation of composite materials with

high electrical conductivity, but also for the preparation of composite

materials with high thermal conductivity. In Japan, high thermal conductivity

plastics prepared by combining low melting point alloys with polymers have been

successfully developed.

Another form of polymer-based conductive

composites that use a low melting point alloy as a conductive filler is an

adhesive. In the electronics industry, in order to replace lead-containing

solders, conductive adhesives composed of polymer collectives and conductive

fillers such as silver sheets have been developed. However, such conventional conductive

adhesives have high and unstable connection resistance and low impact strength.

In order to improve it, a low-melting alloy was added to the conventional

conductive adhesive to produce a new conductive adhesive. The connection

structure of the new conductive adhesive was characterized by SEM, optical

microscope, etc. The results showed that after the resin was cured, a metal

connection was established between the conductive particles and between the

conductive particles and the circuit. This new type of conductive adhesive has

a much lower volume resistance than conventional conductive adhesives,

especially the connection structure formed in the circuit has a lower initial

continuous resistance, and a more stable connection resistance than using a conventional

conductive adhesive, all in the conductive adhesive The use of a low melting

point alloy as a conductive filler can reduce the adhesive resistivity and

improve the connection conductivity.

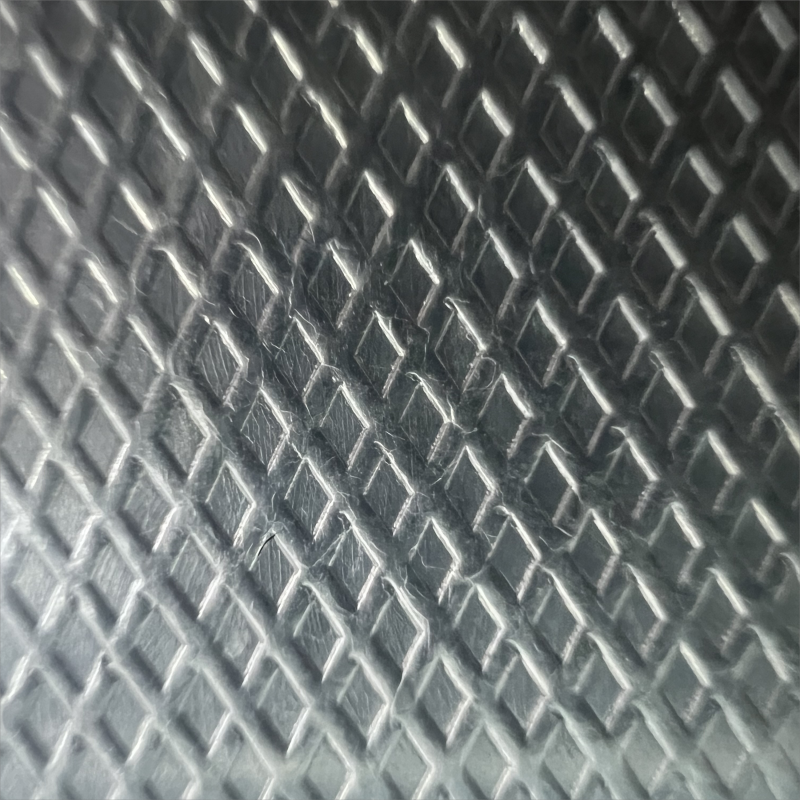

The combination of the low melting point alloy and the polymer can improve the processing property of the polymer. Under appropriate preparation conditions, the obtained composite material has high electrical conductivity and excellent mechanical properties. In other words, the price performance and performance of the material are perfectly unified. It is beyond any other filler system such as carbon black, carbon fiber, metal fiber, metal foil and so on. This shows that low melting point alloys are a very promising functional material.