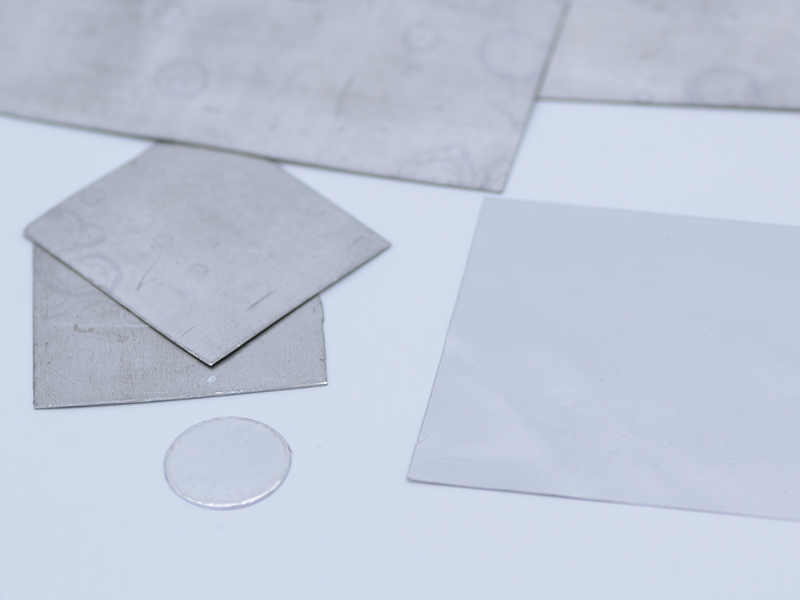

Metal thermal pad as one of the important techniques to enhance heat transfer, is widely used to improve the heat transfer rate of solid wall. Such as aircraft, air conditioning, electronic components, motor vehicle thermal conductivity, Marine thermal conductivity and so on. The research on the heat transfer enhancement of thermal conductive pad has attracted the attention of many researchers at home and abroad, such as the research on the natural convection of thermal conductive sheet and the research on the forced convection of thermal conductive sheet.

Heat conduction pad is

mainly used to strengthen the heat conduction of the heating surface to the

air, so we take the heat conduction sheet in contact with the air as the

research object.

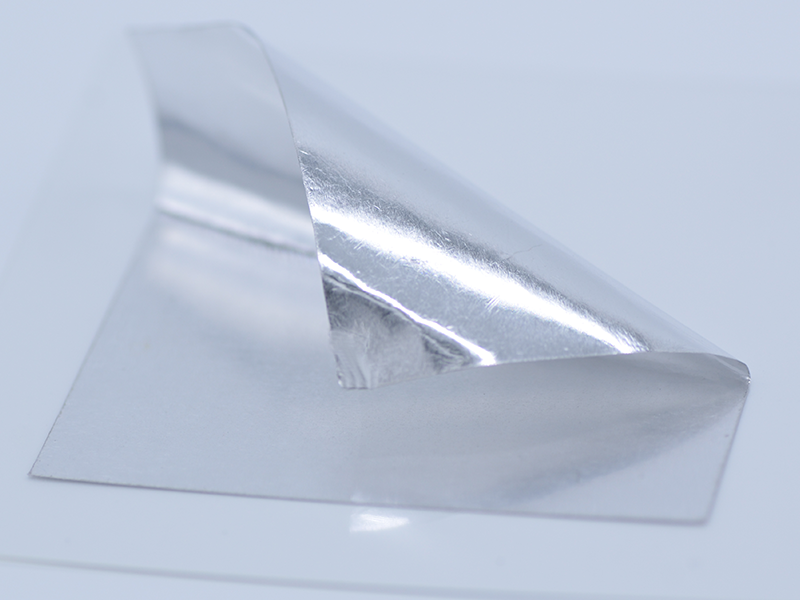

Due to the low surface

temperature (generally no more than 250 ℃) of the thermal conductive pad, the

radiative heat transfer ratio of the thermal conductive pad group to the air is

less than 3% of the total thermal conductivity. Therefore, the heat conduction

between the surface and the surrounding environment is mainly convection heat

transfer.

Influence of height on the

heat conduction of heat conducting pad: increasing the height of heat

conducting pad H can increase the heat exchange area A, thus achieving the

purpose of strengthening heat transfer. However, increasing the height will

reduce the local heat transfer coefficient on the top of the heat conducting

sheet and lead to the decrease of the average heat transfer coefficient. In

addition, the height also affects the temperature drop from the base surface of

the heat conducting sheet to the end. The higher the height, the greater the

temperature drop, resulting in a decrease in the average temperature difference

between the surface and the surrounding atmosphere, which is not conducive to

heat conduction.

In fact, the height of the

heat conductor will also be limited by the overall size of the machine.

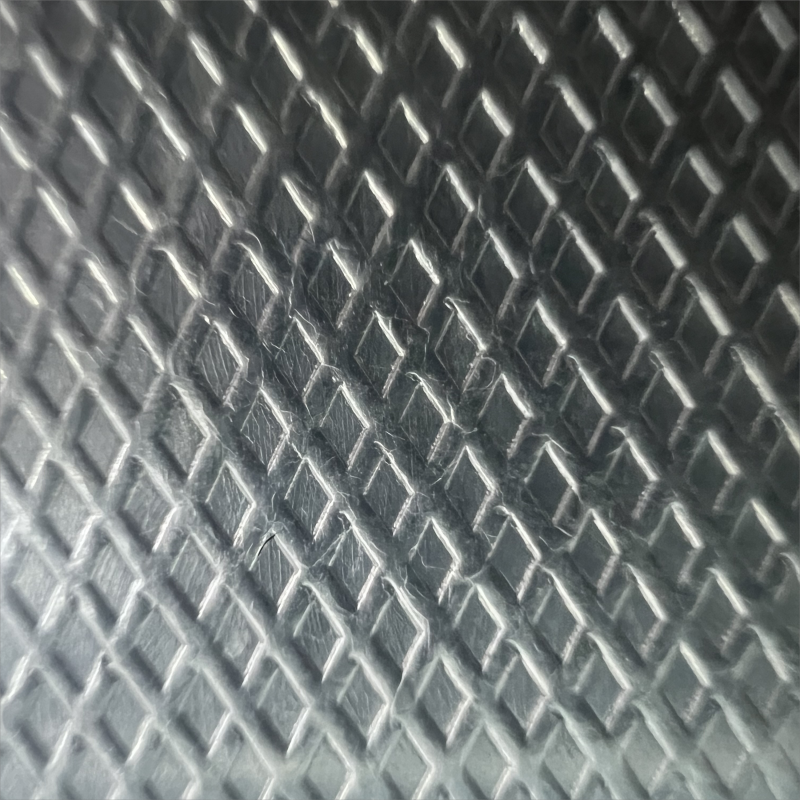

Influence of thickness on the heat conduction of heat conducting sheet: the thinner the heat conducting sheet is, the more heat conducting sheet can be loaded per unit length, thus increasing the heat conducting area and strengthening the heat conducting pad; Along with the rising of the slice thickness of thermal conductivity, thermal conductivity and surface atmosphere around the average heat transfer temperature difference Δ T decreases, which is harmful for thermal conductivity. In practical applications, thickness is often limited by the technological level. Generally, the thickness of the casting heat conducting sheet shall be no less than 2 mm, and the thickness of the machined heat conducting sheet shall be no less than 1 mm.