As the functions of intelligent devices in the 5G era become more and more complex, the integration of chips and modules and the density of components increase dramatically, resulting in the continuous increase in power consumption and heating density of devices.

Therefore, new heat-conducting materials have become an important

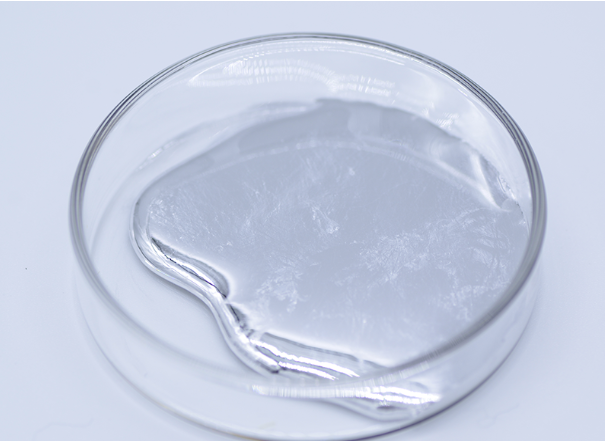

research topic.Liquid metal thermal interface materials have become popular

because of their high thermal conductivity, good wettability, stability, and

wide applicability of materials that can fully fill the void of the contact

surface under low installation pressure.

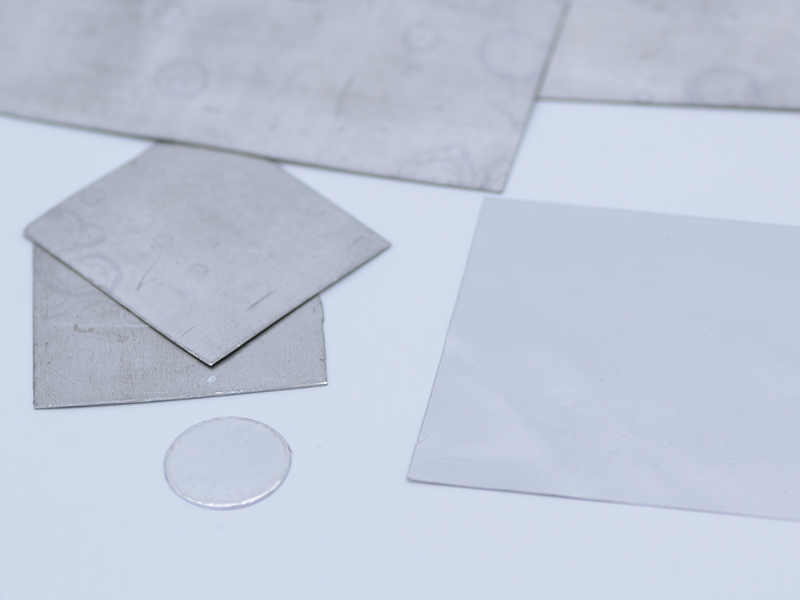

Liquid metal forming process and control, hydraulic characteristics and flow conditions of liquid metal filling process filling process has a great impact on the casting quality and may cause a variety of defects, such as cold insulation, inadequate pouring, inclusion, porosity, sand inclusion, sand adhesion and other defects, are generated in the case of unfavorable liquid metal filling.

It is very important

to design the pouring system to make the liquid metal fill the mold cavity

smoothly and reasonably.Only mercury is a liquid metal, while gallium, rubidium

and cesium are low-melting metals.

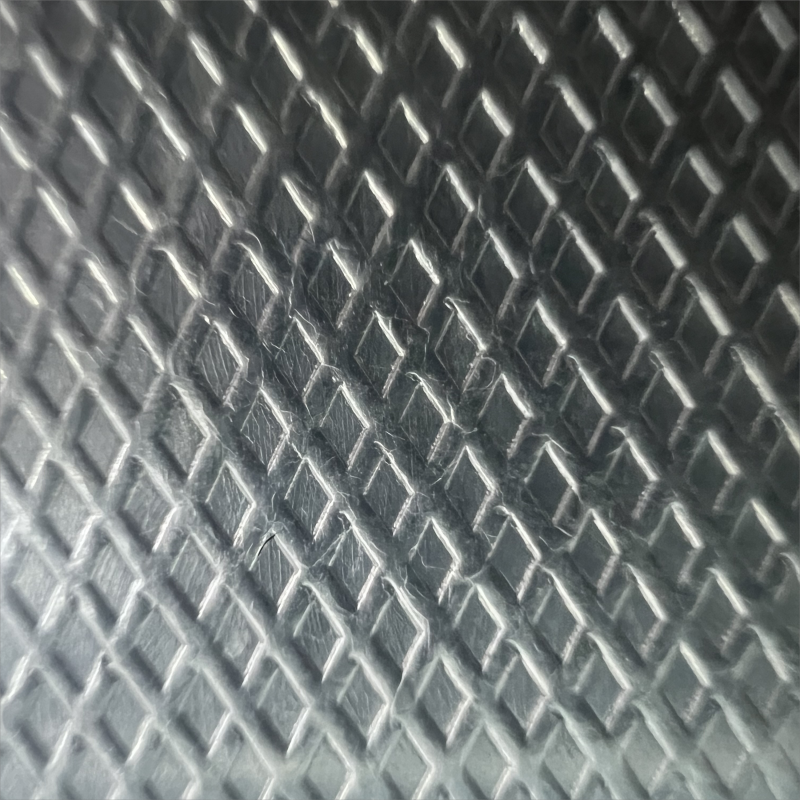

In the field of electronics, liquid metal can be used as ink for 3D printing to directly generate electronic circuits. Compared with traditional metal, its printing temperature and equipment cost are greatly reduced, and manufacturing time is shortened, which can realize personalized customization.

In medicine, liquid metals have good biocompatibility with the body and can be used to connect electrical signals to repair broken nerves.In the mechanical field, compared with traditional polymer materials, liquid metal is self-driven, deformable, and able to run and jump, providing a path for the development of flexible robots.In terms of heat dissipation of high power density devices, the heat transfer performance of liquid metal is obviously better than that of conventional working media such as water.At a low flow rate, the device surface temperature can be kept low, suitable for cooling products and cooling solutions in the cooling field and market areas with cooling needs.