low melting point At present, the main cooling technology is air cooling, heat pipe, water cooling and so on.Air cooling technology has limited thermal conductivity and can only be applied to low-power electronic products.The heat pipe is better than the air cooling, but there is the burning limit, and even the pipe rupture failure phenomenon;Due to evaporation, leakage and other problems in the process of operation, water-cooled cooling is easy to lead to device aging, and the requirements for liquid and flow pipe are also high.

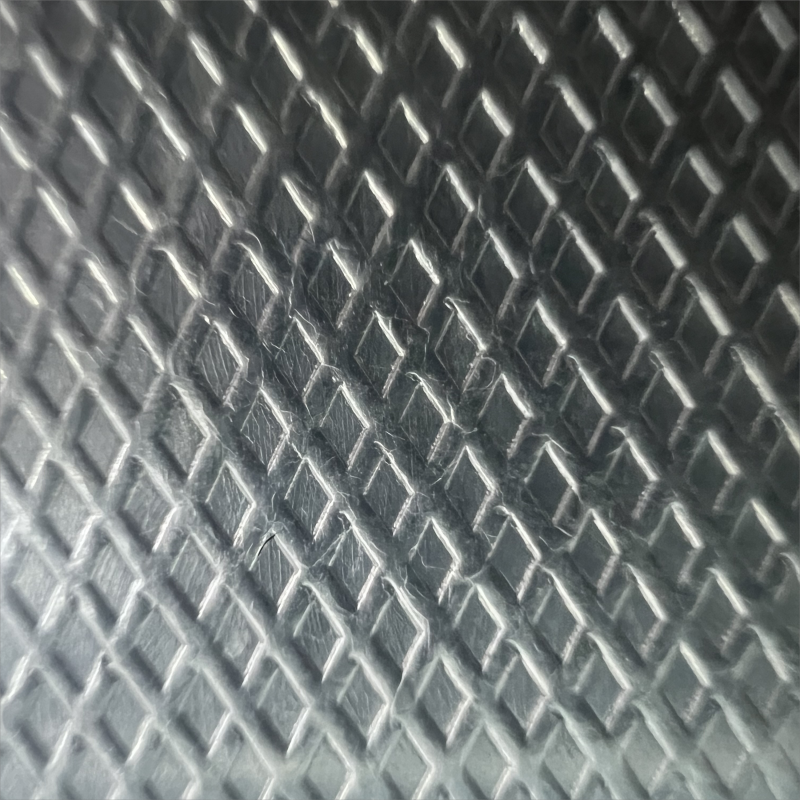

The radiator that liquid metal makes has the advantage that this traditional radiator cannot compare, that is collect efficient, compact, safe, quiet in an organic whole.

It has good thermal conductivity and specific heat capacity, but the volume does not increase at all. The same volume brings better performance, and the compactness is vividly reflected.

Liquid metal will not leak, not easy to evaporate, will not deteriorate, safe operation, long service life. Due to the built-in electromagnetic pump in the heat dissipation pipeline, the pressure gradient is generated by the electromagnetic force to push the liquid forward without any noise, so that users can enjoy the silent radiator.

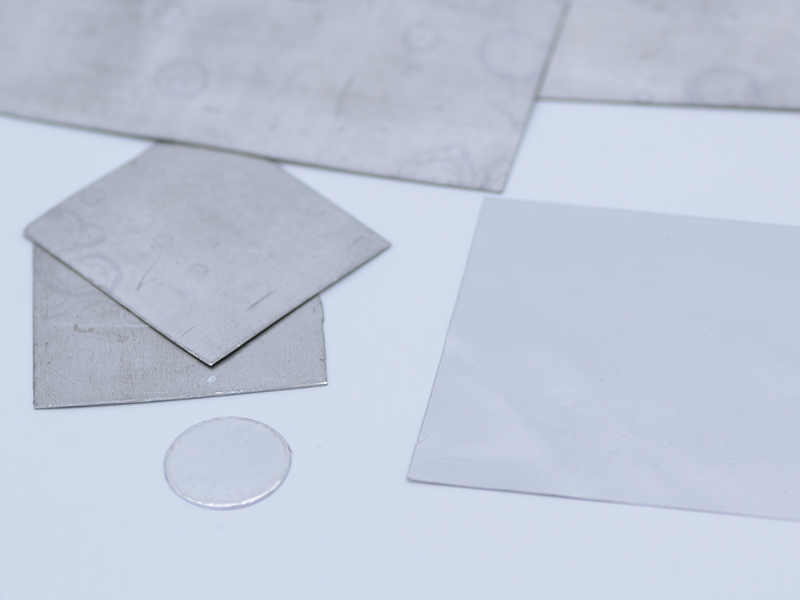

The alloy of gallium metal is used as the heat conducting agent of radiator, with low melting point, non-toxic and harmless, fast heat absorption and high boiling point.

Liquid metal cooling technology can not only be applied to CPU cooling, its core technology can be extended to more aspects, including the instrument industry, steel manufacturing, solar energy capture, national defense, etc. Due to the wide application of various kinds of chips and optoelectronic devices, the corresponding cooling technology has a huge market demand.

According to the data, the world market for manufacturing components such as fans and fins used in computer cpus, for example, is about $5 billion to $10 billion a year. With the increasing power consumption, the price of chip cooling solutions has also increased dramatically, and the corresponding market demand has also increased. This undoubtedly provides the broad development space for the liquid metal heat dissipation technology.